Overview

The powder / air mixture is extracted from the powder booth enclosure through specially configured, self-cleaning duct work. This design eliminates the possibility for powder contamination in the extraction duct.

Convenient clean-out access ports are provided for routine maintenance.

Tangential air movement within the trapezoidal design separates powder from the air stream and is proven efficient to 97%.

MS Cyclone Features:

- Cyclone capacity range: 4,000 to 28,000 m³/hr. (2,400 to 16,800-CFM).

- Trapezoid conical design, top to bottom for most efficient automatic cleaning and most efficient powder recovery.

- Provides overall powder reclaim efficiency to 97%.

- Swing-out cone for ease of access and maintenance.

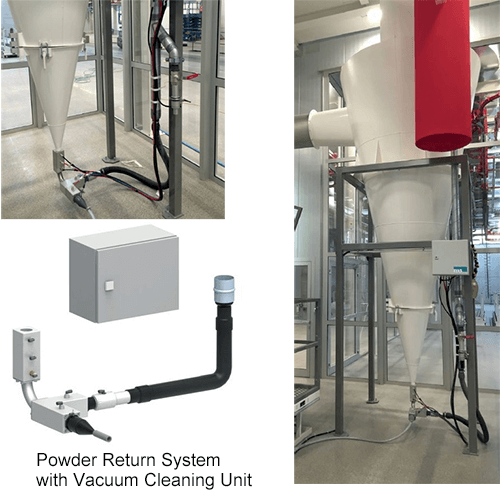

- Powder feed return peristaltic pump system for reclaim, or spray to waste operation.

- Integrated system powder vacuum cleaner.

- No sieve screen in cyclone tail section eliminates potential for powder contamination in cyclone.

Literature

Overview

The powder / air mixture is extracted from the powder booth enclosure through specially configured, self-cleaning duct work. This design eliminates the possibility for powder contamination in the extraction duct.

Convenient clean-out access ports are provided for routine maintenance.

Tangential air movement within the trapezoidal design separates powder from the air stream and is proven efficient to 97%.

MS Cyclone Features:

- Cyclone capacity range: 4,000 to 28,000 m³/hr. (2,400 to 16,800-CFM).

- Trapezoid conical design, top to bottom for most efficient automatic cleaning and most efficient powder recovery.

- Provides overall powder reclaim efficiency to 97%.

- Swing-out cone for ease of access and maintenance.

- Powder feed return peristaltic pump system for reclaim, or spray to waste operation.

- Integrated system powder vacuum cleaner.

- No sieve screen in cyclone tail section eliminates potential for powder contamination in cyclone.